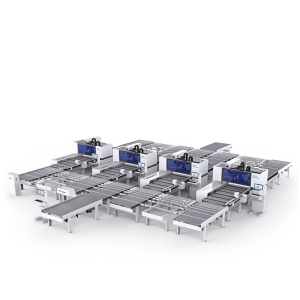

KD-612KS

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

Double-drill package six sides NC drilling center has double-drill packages for simultaneous processing and more efficiency. Single-handed operation, small workload, can be directly connected with a variety of split software. It is mainly used for six faces (hinge holes, through holes, semi-through holes) of various kinds of artificial boards, horizontal drilling, and can simultaneously process symmetrical hole positions, also can do hogging and milling with small spindles. |

|

| 1.64mm min drilling distance between 2 drill bit package during simultaneous processing | |

| 2.With double gripper and long guide rail,gripper max speed up to 140m/min,auto detect hole position to avoid gripper exchange time. Gripper trip up to 5.5 meter,big board can working by one time catch,reduce processing time. | |

| 3.Adopt double translation air flotation table,move flexibly according to the hole position to improve the drilling accuracy and avoid fouling at the bottom. | |

| 4.Adopt double positioning mode,more accurate and efficient positioning of different panels. | |

| 5.Adopt belt conveyer dust collection,centralized remove all dust which fall into machine. | |

| 6.Software can simulate processing path,predict the processing time; | |

| 7.Processing record statistics,view production progress in real time. | |

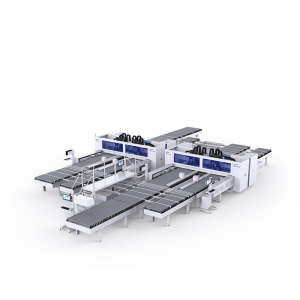

KD-612KSZ

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

Double-drill package ,six sides NC drilling center has double-drill packages and 5 types ATC for simultaneous processing and more efficiency. Single-handed operation, small workload, can be directly connected with a variety of split software. It is mainly used for six faces (hinge holes, through holes, semi-through holes) of various kinds of artificial boards, horizontal drilling, simultaneously process symmetrical hole positions, also can do hogging and milling with small spindles. |

|

| 1.5 types ATC for spindle, easier to handle hogging, milling, lamella and other crafts; | |

| 2.With double gripper and long guide rail,gripper max speed up to 140m/min,auto detect hole position to avoid gripper exchange time. Gripper trip up to 5.5 meter,catch big board by one time ,reduce processing time. | |

| 3.Adopt double translation air flotation table,move flexibly according to the hole position to improve drilling accuracy and avoid fouling at the bottom. | |

| 4.Adopt double positioning modes,more accurate and efficient positioning of different panels. | |

| 5.Adopt belt conveyer dust collection,centralized remove all dust which fall into machine. | |

| 6.Software can simulate processing path,predict the processing time; | |

| 7.Record processing statistics,view production progress in real time. | |

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ