KA-2713 Yükleme Asansörü

KDT-533

Products Details

3 head boring machine. The boring unit can be rotated 90 degree

TECHNICAL FEATURES Machine Video

KHA-9713 Boşaltma Asansörü

KHG-230 Frame Type Loader/Unloader

The frame type stacker loading and unloading equipment is flexible in application, does not require excavation, and has a small footprint. It can be connected to edge banding machines and drilling equipment. |

|

| 1.High-strength frame structure, high-quality rubber rollers, and stable performance in long-term use | |

| 2.The multi-point suction cup gripper can grab multiple side-by-side panels at the same time, and can load or unload 11 times per minute | |

| 3.The touch screen is easy to operate and can realize a variety of loading and unloading modes. The action sequence of loading and unloading is realized through sensors and software | |

KHG-280/980 Gantry Loader/Unloader

【 Automatic feeding machine 】 Heavy gantry stacker loading and unloading equipment, with dual workstations - left and right lifting platforms that can alternately stack up and down materials. It is flexible and efficient in application, suitable for mass production, and can be connected to edge banding machines and drilling equipment. |

|

| 1.High strength gantry structure and lift table, stable performance in life-time service. | |

| 2.Double lifting table can achieve a continuous process by feeder and stacker. Lifter automatically move upwards or downwards to the same level with rollers, save time in catching panels. | |

| 3.Catching work piece by grippers with several vacuum cups, 12-15times/min for the loading or unloading . | |

| 4.Convenient program In man-computer interface, realize various mode in loading and unloading , and realize an action sequence of loading and unloading by sensor and software. | |

| 5.Safety protection has a door sensor, door open when feeder in and stacker out. | |

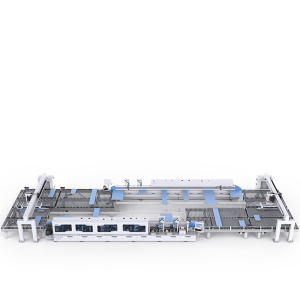

KHG-930 Frame Type Loader/Unloader

The frame type stacker loading and unloading equipment is flexible in application, does not require excavation, and has a small footprint. It can be connected to edge banding machines and drilling equipment. |

|

| 1.High-strength frame structure, high-quality rubber rollers, and stable performance in long-term use | |

| 2.The multi-point suction cup gripper can grab multiple side-by-side panels at the same time, and can load or unload 11 times per minute | |

| 3.The touch screen is easy to operate and can realize a variety of loading and unloading modes. The action sequence of loading and unloading is realized through sensors and software | |

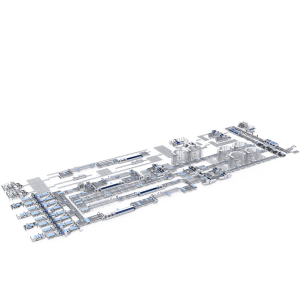

KN-6410K

Products Details

TECHNICAL FEATURES Machine Video

KDT high-quality PTP machining center, mainly used for custom furniture composite processing, which can be milled, cut, drilled and so on. The software linkage is open, which can perfectly connect with the processing data generated by the third-party front-end design and order splitting software, which is convenient to operate and easy to proceed |

|

| 1.Dual work station, 2 workpieces independently works in each station, easy operation and efficient work | |

| 2.6 groups of rails table, flexibly combine,easy to feed in and feed out workpiece | |

| 3.16-post servo ATC satisfy demands on machining with various tools and realize accurate and fast tools change | |

| 4.Drill head: 12V+8H+1S ,realizing efficient drilling and grooving | |

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ