TECHNICAL FEATURES

| Model: KS-843D | |

|---|---|

| Maximum working dimension | 4300L * 4300W * 120H |

| Min. working dimensions Lenght(L)Width(W) | 34L * 45W |

| Saw carriage forward speed (m/min) | 95 |

| Saw carriage backward speed (m/min) | 120 |

| Max. saw projection (mm) | 120 |

| Main saw balde diameter (mm) | 450 / 75 |

| Scoring saw diameter (mm) | 200 / 50 |

| Main saw motor power (kW) | 18.5 |

| Scoring saw motor power (kW) | 2.2 |

| Number of gripper | 11 |

| Total Installation Power (kW) | 35.5 |

| Overall Dimensions (L)(W)(H)(mm) | 8075L * 6595W * 2030H |

| Weight (kg) | 6300 |

Machine Video

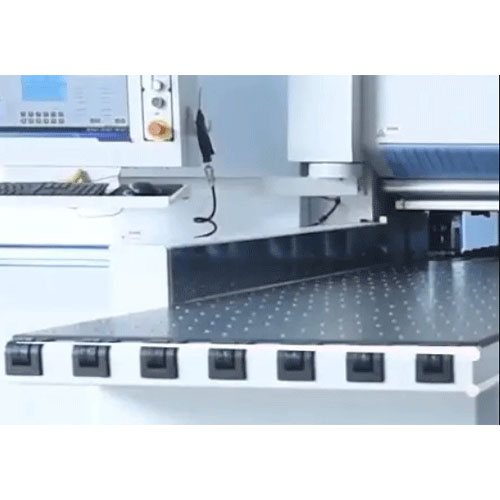

MAIN FRAME

MONOBLOCK FRAME

Reinforced frame, annealed, sanded and one-time forming, durable and not easy to be deformed, stable in running.

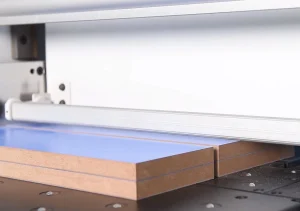

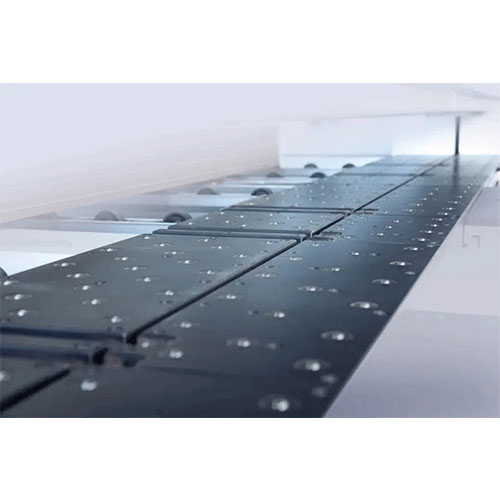

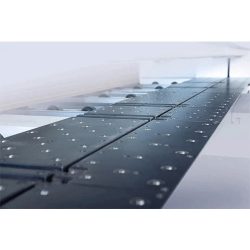

CUTTING LINE

Working table is applied with pneumatic floating balls on top, effectively protect panel being scratched, and easy to move the panel to the working area.

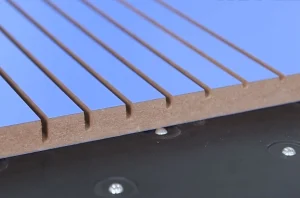

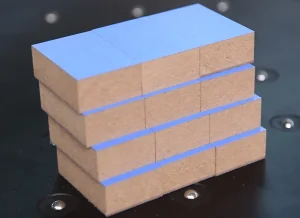

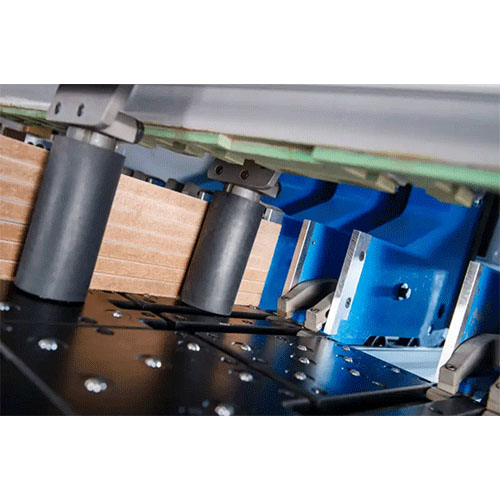

GROOVING

The main saw adopts servo control for lifting, ensuring a best sawing quality and achieving slot function. aracılığıyla, kalma yüksekliği ekrandan otomatik olarak ayarlanır, istenilen derinlikte kanal açılır.

GENERAL FEATURES

FAST CUTTING BUTTON

Qucik-start device Extra add the continuous cutting pull rod on the air floating table, it is more convenient and faster to start cutting.

AIR FLOATATION TABLES

The first floating table is 2300x800 mm

AIR FLOATATION TABLES

3 floating tables are 1900x540 mm

GENERAL FEATURES

SIDE ALINGER

There is double side alinger. It make a better alinging when there high stack.

Side roller are moving on prismatic guieds and it gets the position according to the width of the panel. It is fast and accurate

MINIMUM CUTTING DIMENSIONS

34 x 45 mm

PRESSURE BEAM

CLEVER PRESSURE BEAM

The pressure beam rises up according to the height of the panel stack height. It saves time

UPPER PRESSURE BEAM SAFETY

The pressure of the upper beam is controlled and make the safety for the operators.

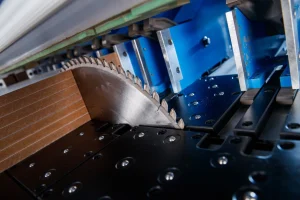

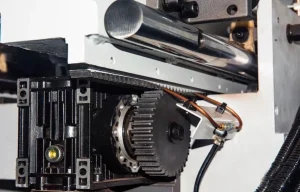

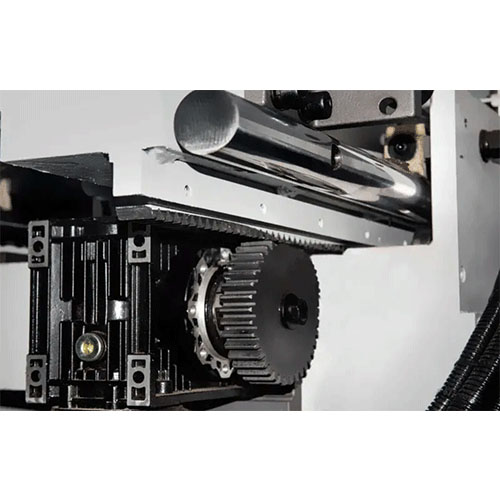

SAW CARRIAGE UNIT TRANSMISSION SYSTEM

SAW CARRIAGE UNIT

Saw units are seperated and has each motors. Main saw up/down movement is controlled by servo system.

SAW CARRIAGE SYSTEM

Saw carriage is moving on the rounded guides and transmited by rack and pinion system with a servo motor. The accurancy is +-0,1 mm

PUSHER UNIT

PUSHER

Pusher unit is produced from steel

Number of grippers are 10 and the grippers have double fingers

GRIPPER

It makes a better clamping via the double finger function.

GENERAL FEATURES

MOVABLE CABLE CANAL

Flexible cable carriage, makes a soft movement for cables

CE NORM(ONLY FOR CE COUNTRIES)

There is fence covering the machine

ELECTRICAL CABINET

There is an international brands for the components

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

Reviews

There are no reviews yet.