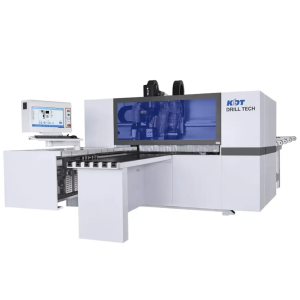

TECHNICAL FEATURES

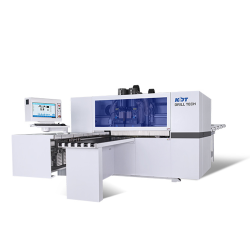

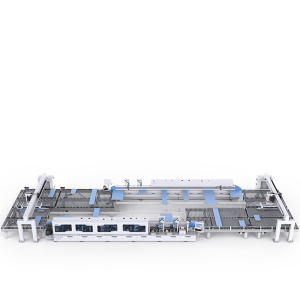

| Modeli: KD-612KS | |

|---|---|

| Panel Lenght (mm) | 200-2800 |

| Panel Lenght (mm) | 50-1200 35-50 (L≤1000) |

| Panel thickness(mm) | 9-60 |

| Max. Feeding Speed (m/min) | 140 |

| Number of drill bits | Üst dikey matkap 26V + yatay matkap 12H + alt dikey matkap 9V Üst 26V+12H+Alt 9V |

| Electrospindle(kW) | 1*5.5 1*3.5 |

| Total Installing Power(kW) | 28.22 |

| Overall Dimension L*W*H (mm) | 7508L*2855W*2190H |

| Number and Diameter of Dust Extruction Hoses | Ø200*2+Ø100*2 |

Machine Video

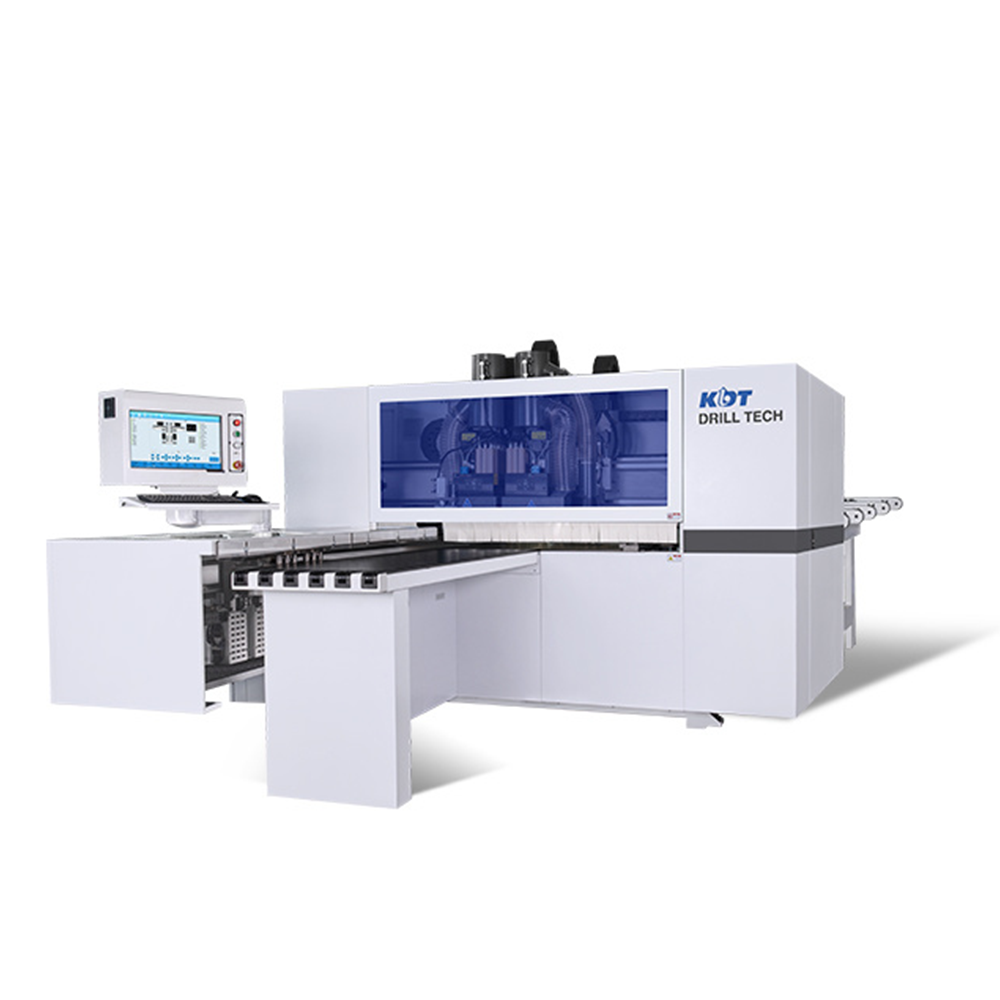

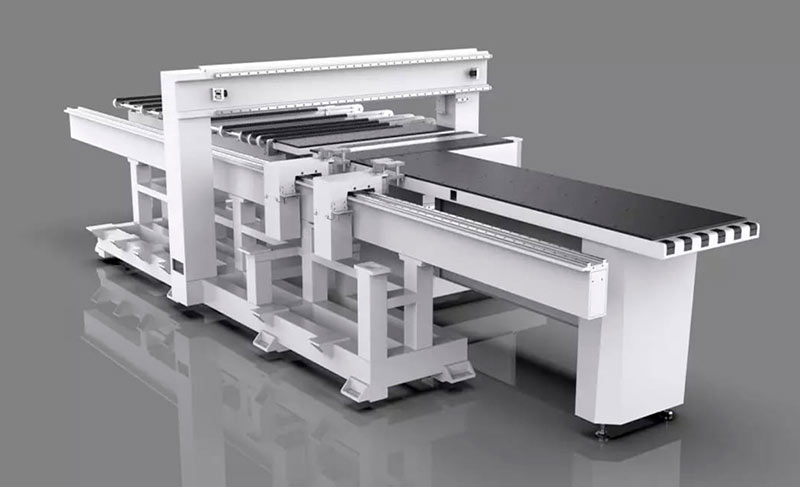

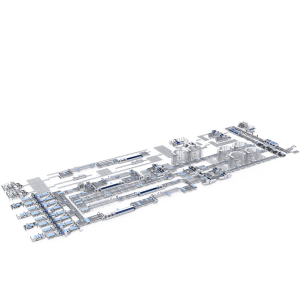

MACHINE FRAME

Heavy-duty machine body

The frame is processed by robot welding, annealing, shot blasting, sandblasting, finishing and other processes, effectively ensuring long-term stable operation.

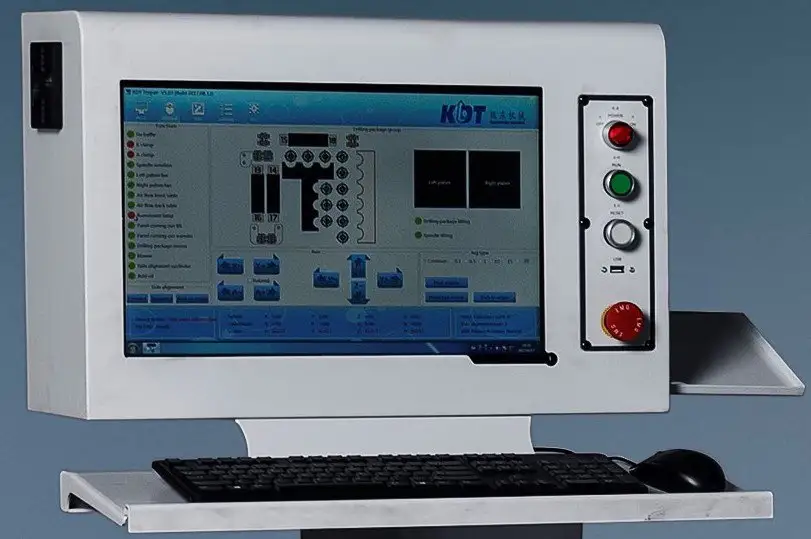

NEW CONTROL SYSTEM

New control system

Simulate processing path to predict processing time.

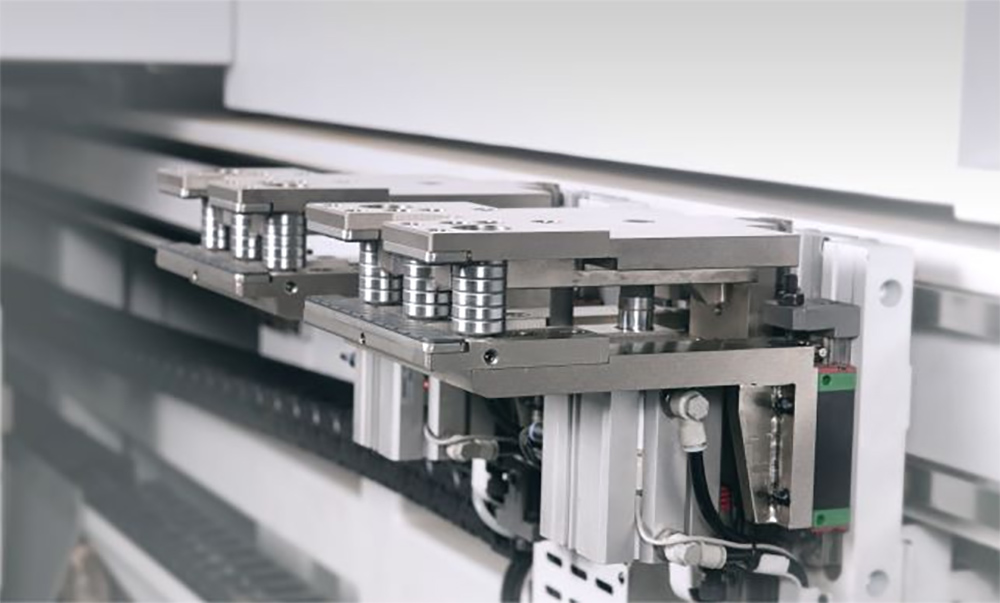

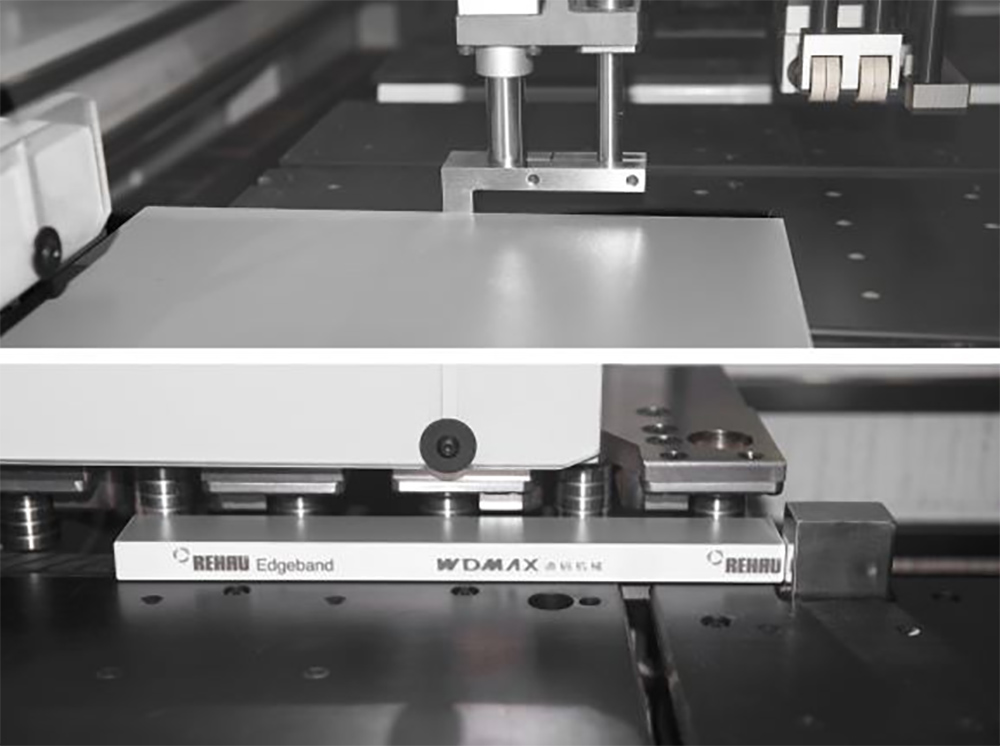

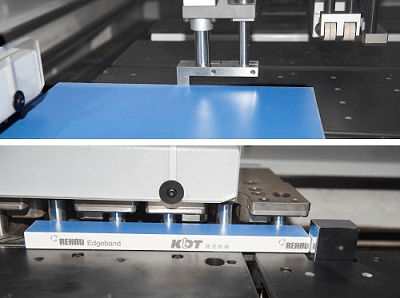

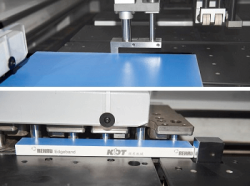

ELECTROSPINDLE PLATE(PATENTED)

Air pressure plate (patent)

The pressure plate covers a wide area, with small processing vibration and high precision, which protects the plate from being scratched.

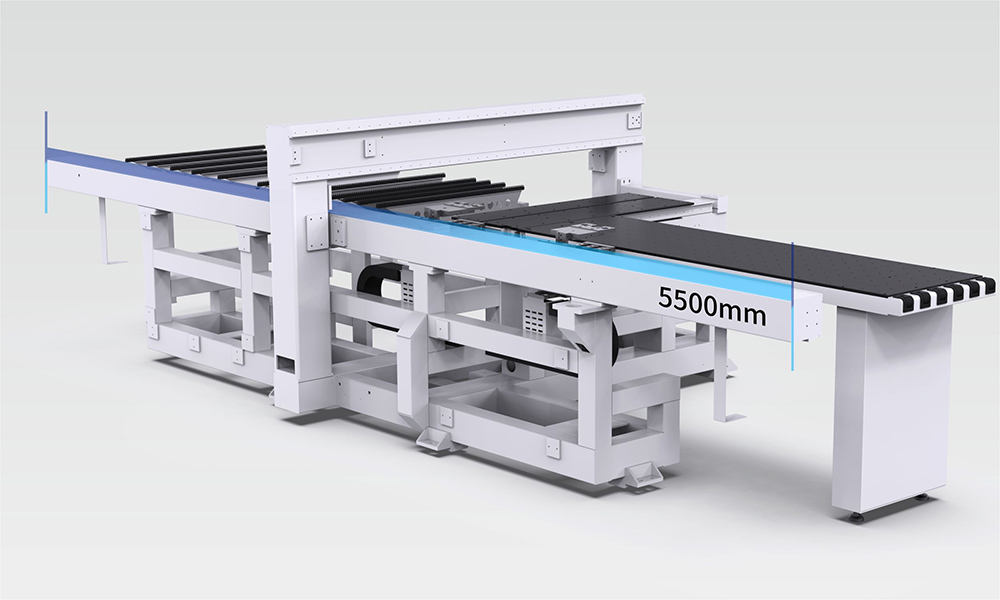

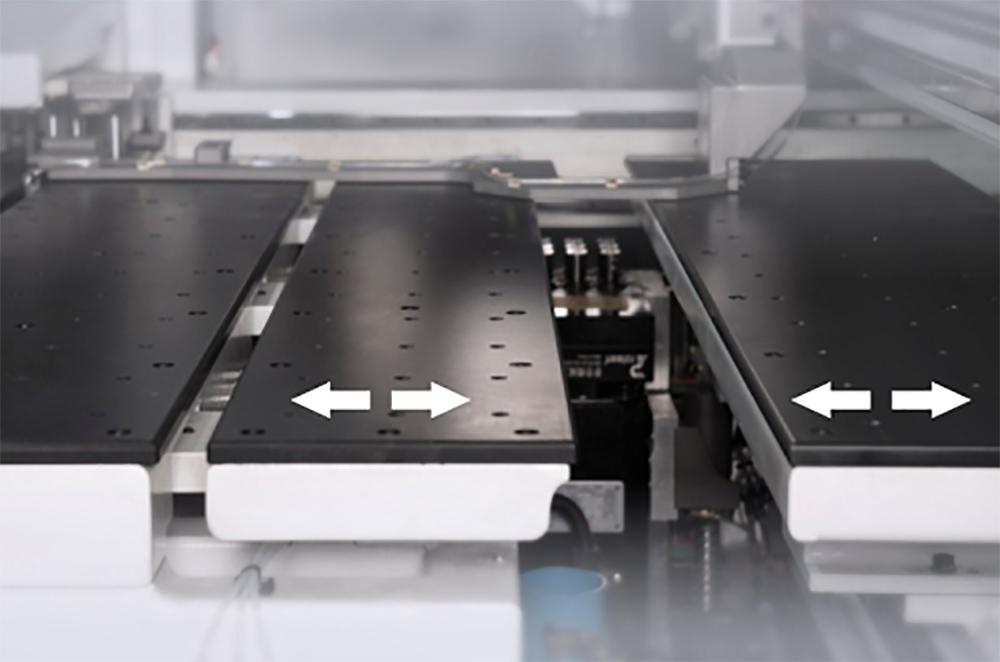

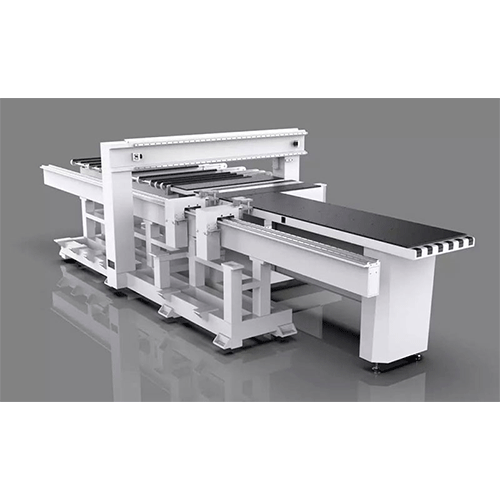

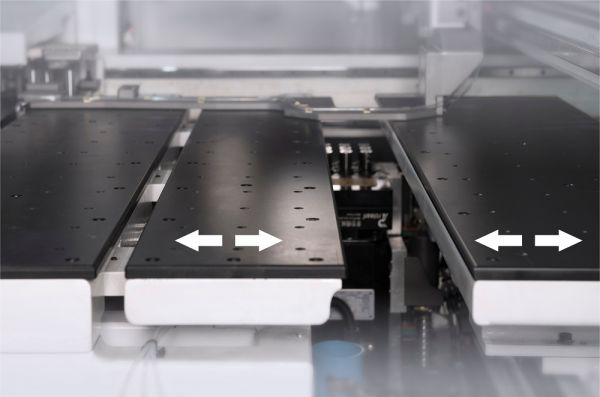

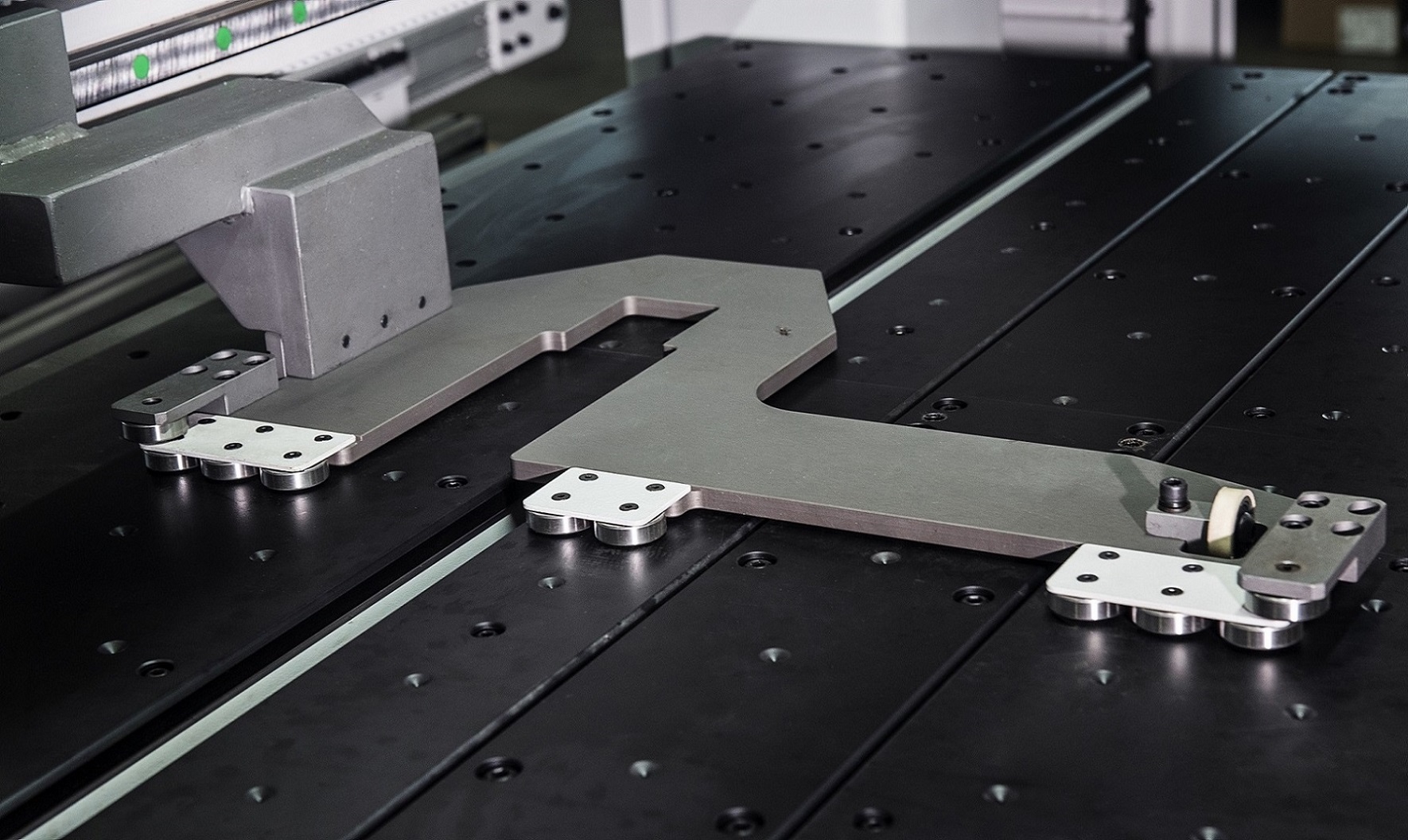

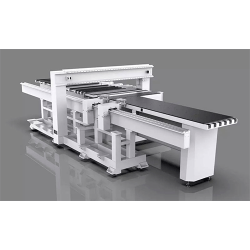

SUPPORT TABLES(PATENTED)

Double translational air floation table(patent)

Move flexibly according to the hole position, reasonably support the panel, improve the drilling accuracy, and avoid dust accumulation at the bottom

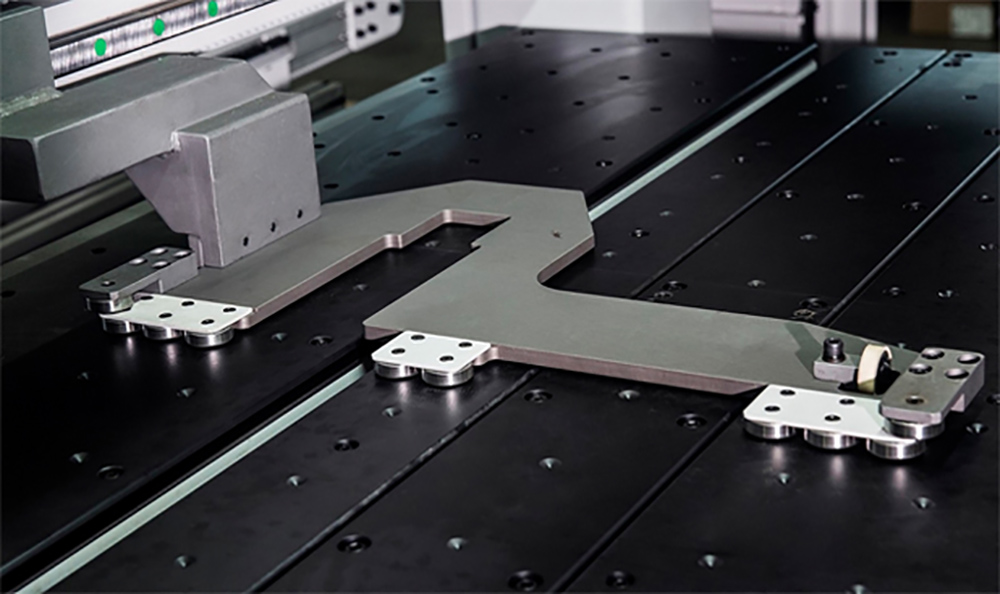

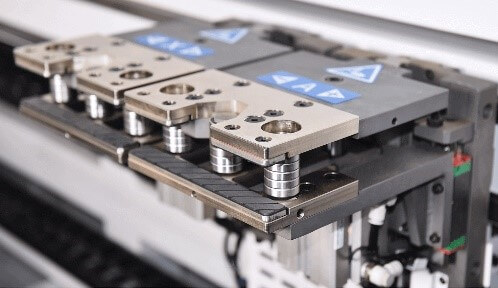

CLAMPS

Position rod with three bearings

Accurately positioning for small boards, no scratch when change grippers

SCANNER

Scanner

Scan label to recognize working file(standard with scan gun)

AUTOMATIC SIDE ALIGNER

Side Aligner

Side aligner with double sliding block ensures a higher accuracy

DATA FORMATS

Compatible with diversified data formats

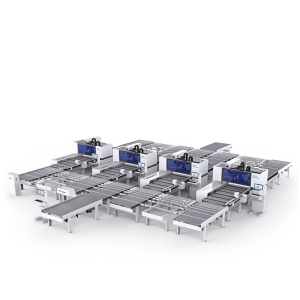

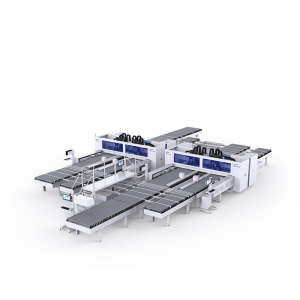

Compatible with diversified data formats, realizes the intelligent production and information management of customized furniture. Quickly responds to market demand.

HIGHLIGHTS

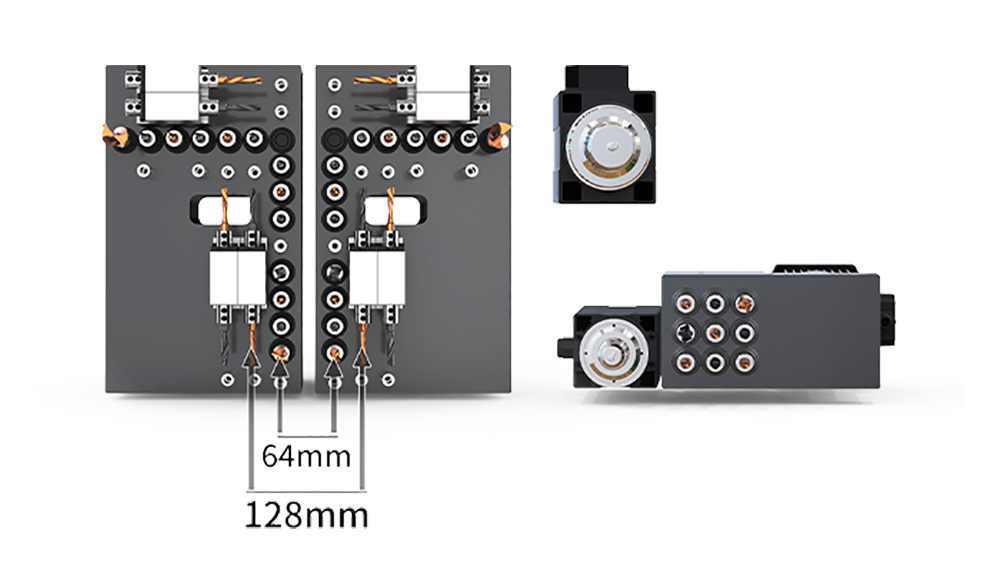

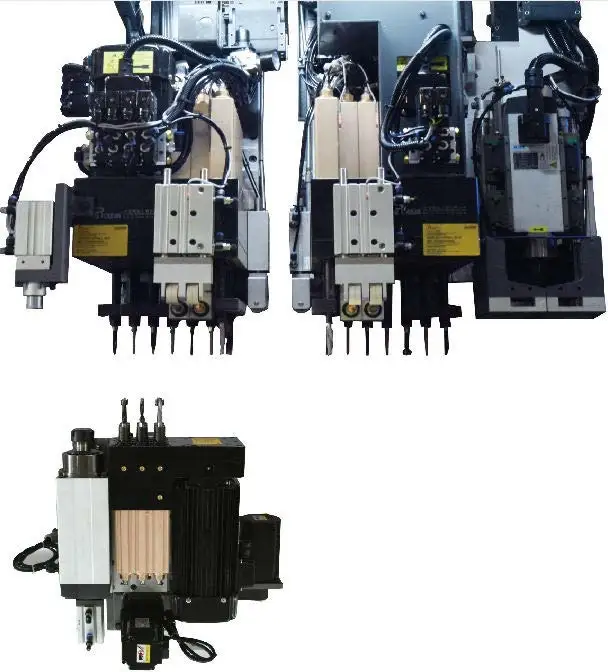

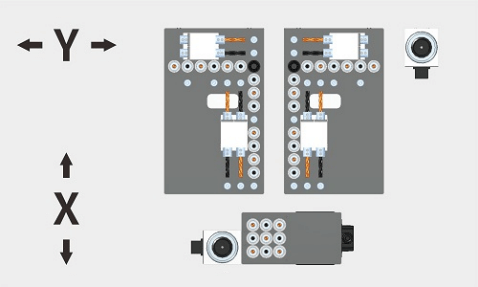

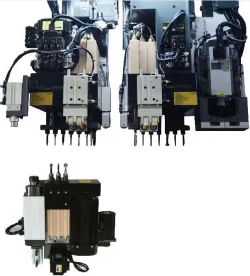

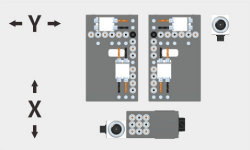

HEAD CONFIGURATION

Double upper drill package

Drill package:UP:26V+12H BOTTOM:9V

HIGHLIGHTS

DUST COLLECTION

Belt conveyor dust collection:centralized remove all dust which fall into machine.

HIGHLIGHTS

DOUBLE REFERANCE STOPS

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

Reviews

There are no reviews yet.