Teknik Parametreler

Model:KHA-1713TS

| 1.Panel length(mm) | 4260 |

| 2.Panel width(mm) | 2150 |

| 3.Panel thickness(mm) | 10-25mm |

| 4.Stack height(mm) | 500 |

| 5.Load bearing capacity(kg) | 3500 |

Ürün Videosu

BAŞLIK EKLENECEK

Açıklama

açıklama

Açıklama

açıklama

Table unit

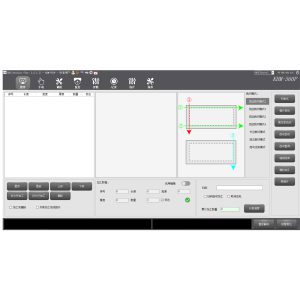

ONLINE CONTROL

computer integrated type control

BAŞLIK YAZILACAK

Açıklama

Açıklama

Açıklama

Açıklama

PC intelligent control system

PC control, support multiple sawing modes, easy to operate.

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

FUARIMIZA BEKLİYORUZ

12-16 EKİM 2024

TUYAP FUAR MERKEZİ

Değerlendirmeler

Henüz değerlendirme yapılmadı.